Turning and milling: EOS, a benchmark in precision machining

Turning and milling is a crucial process in the manufacture of technical parts. EOS, a machining specialist based in the Rhône-Alpes region since 2010, excels in these techniques. We offer complete, tailor-made solutions for small, medium and large production runs for manufacturers in all sectors.

With its state-of-the-art machinery and recognized expertise, EOS is the ideal partner formachining services in Lyon and surrounding areas.

EOS machining capabilities: advanced machinery

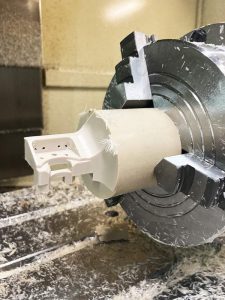

At EOS, the turning and milling process is supported by a complete and modern machine park. Equipped with 2 CNC lathes for turning and 4 CNC machining centers for milling, our company guarantees efficient, high-quality production.

Add to this the presence of 2 industrial 3D printers and a state-of-the-art 3D geometric inspection machine for rigorous quality control, and you have a state-of-the-art logistics tool for producing precise mechanical parts of consistent quality, whether simple or complex, in small or large production runs.

EOS regularly acquires new machines and tools to ensure that it always has the latest generation of top-quality equipment.

The technical expertise and know-how of EOS

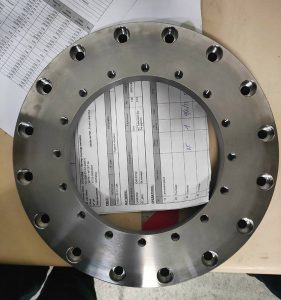

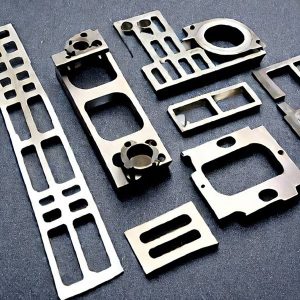

EOS' experience in the precision mechanics sector is a major asset. The long-standing expertise of our staff, combined with in-depth knowledge of machines and parts, enables EOS to produce all types of technical parts, from special machine components to bending parts.

Each range of complete parts is produced through a series ofturning and milling operations in our workshops in the Lyon region. On average, it takes 1h30 to turn, then mill, before turning again if necessary. A surface treatment, such as quenching to make the part more resistant, can in some cases be carried out by a partner subcontractor at the end of these operations.

Impeccable service quality

EOS' strength lies in its customer approach. Our company offers a local service in the Rhône-Alpes region from one end of the process to the other, from the analysis of your needs based on the plans you send us to the delivery of your products.

Every stage in the production of technical parts is managed with the utmost care. For larger production runs, EOS carries out on-site audits and exchanges to help analyze your needs.

Complete, customized machining solutions

EOS stands out for its ability to offer complete, tailor-made turn-mill machining solutions. Whether for small or large production runs, our company ensures consistent quality thanks to its advanced machinery and strict quality control procedures. The diversity of standard and special machining tools, combined with a variety of calibrated inspection tools, enables EOS to meet all market requirements.

This makes EOS the ideal partner for all manufacturers looking for precision machining solutions.

Contact us today to present your project and get your free quote!