Tube bending: Services and benefits with EOS

Tube bending is a demanding speciality requiring in-depth technical expertise.

EOS, the European leader in this field, offers a range of services tailored to large industrial groups and small and medium-sized bending companies in France and beyond.

Precision mechanics: the heart of EOS service

At the heart of EOS’ service lies precision engineering, backed up by long-standing expertise. Whether it’s creating new machines, retrofitting, manufacturingbending tooling, or maintaining bending machines, EOS guarantees flawless reliability.

Several members of our team have over 30 years’ experience in this field. This expertise, shared by all the company’s trades, and the diverse profiles of our engineers and technicians, enable us to provide you with genuine know-how and irreproachable results, perfectly adapted to the current requirements of the sector and the specific constraints of your business.

Design of custom bending machines and tooling

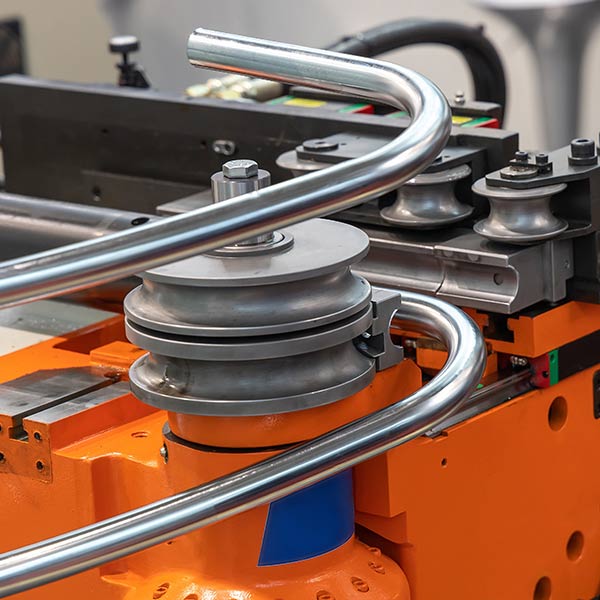

Specializing in the Siemens range of products for digital bending machines, EOS excels in the custom design of CNCbending machines. We work with you to analyze your needs and tailor our proposals to your business requirements and industry standards.

We also design and manufacture bending tools specifically adapted to your machine, whether it’s one of our own design or not. Whether you need to bend small-diameter tubes or large-scale industrial parts, our tools are designed to meet your exact requirements.

Rebuilding bending machines: the retrofit option

In addition to designing and manufacturing tube bending machines, EOS also specializes in rebuilding bending machines. This retrofit service makes it possible to keep an existing machine, which is often difficult to replace, while adapting it to the latest technologies.

Taking into account your budget, desired precision and cycle time, EOS offers an efficient updating system. This process is essential for those wishing to keep their machines running while keeping pace with current industry and safety requirements.

What’s more, retrofitting your machine will help your company achieve its sustainable economic and environmental objectives, with an average of 90% of the machine’s mass saved from disposal.

Support and training: the EOS advantage

EOS’ added value does not end with the design and manufacture of new bending machines and tools, and with rebuilding. We also offer a complete range of bending machine commissioning, maintenance and training services.

Whether your staff are novices or experienced, EOS offers dedicated training sessions to ensure that you master the use of your new or rebuilt bending machine.

Thanks to our tailor-made maintenance service, we optimize the longevity and performance of each piece of equipment.

EOS, a partner at your side

By choosing EOS, customers benefit from a true partnership of trust. Every stage, from design to delivery, is validated with the customer, ensuring impeccable quality throughout the process. EOS is committed to offering tailor-made solutions that combine innovation, precision and durability, meeting the stringent requirements of different industrial sectors.

Would you like to make an appointment to design a CNC bending machine , bending tools or retrofit (rebuild) your bending machine? We look forward to hearing from you.